Do you know what kinds of electroplating processes are available?

With the continuous subdivision of industrial production, the emergence of new processes and new materials, the design effect of the application in the actual products is changing with each passing day. Electroplating is a process that Sunny Glassware often involves in the design, and the electroplating effect is a kind of effect that we use for a long time and the process is more mature. The application of this process in our products has been very much. Today, Sunny Glassware takes you to understand the plating process.

The pretreatment process of candlestick electroplating is very important. The coating properties are different from the base metal and have new characteristics. According to the function of the coating is divided into protective coating, decorative coating and other functional coating.Electroplating is the abbreviation of electrolytic gold plating. Electroplating is the plating (products), immersed in the potion containing metal ions to be plated and connected to the cathode, the other end of the potion placed appropriate anode, (soluble or insoluble), through the direct current, the surface of the plating is precipitated a layer of metal film method. Simply understood, it is a change or combination of physics and chemistry. The electroplating methods commonly encountered at present: water solution electroplating (rolling plating, hanging plating, continuous plating), chemical plating.

Electroplating can effectively improve the surface hardness, wear resistance, heat resistance, reflective ability; Local protection and other special properties during heat treatment.

The main purpose of candlestick electroplating is to decorate the appearance of candlestick and make the appearance beautiful.

Candlestick electroplating process is divided into two kinds: internal plating and external plating

Internal plating process: first clean the light cup - cup body kiln baking heating - electroplating machine put aluminum wire/aluminum sheet (aluminum wire volatilization is not complete will lead to light cup coating through, black after spraying color - placed light cup - pre-vacuum-high temperature pumping - aluminum wire volatilization - complete plating cup (about 15-20 'a pot specific time to see the machine).

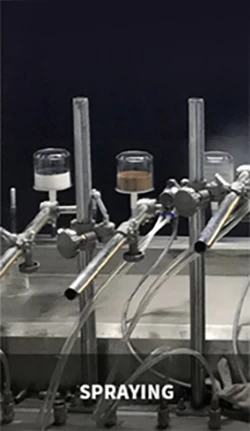

External plating process: light cup single spray color after colorful plating - ion plating - aluminum wire plating - the whole need to wear gloves to prevent the production surface of hand prints - product placement - liquid placement (generally volatile 2 m) - operation panel to start work - finish product coating.

In such a strict process, in order to complete a beautiful and beautiful electroplating glass candle holder works!

Finished product electroplating process glass candle holder (real photo) ↓