How to increase the hardness of glass candlestick?

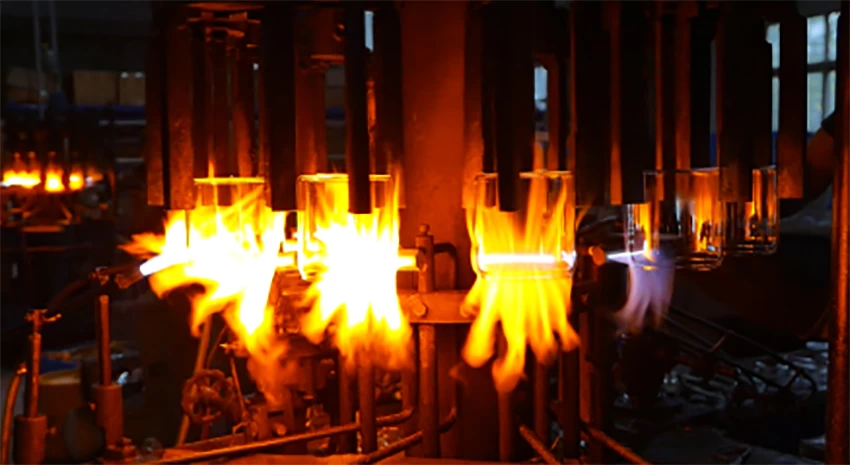

The transparency of the glass candlestick can give customers a clean visual impression. The hardness and quality of the glass candlestick can enhance customer confidence.Sunny Group has offered glassware since 1992 with all kinds of products being exported to more than 30 countries and regions.Sunny glassware Use hot and cold spray to improve the inner and outer walls of glass bottles and the quality of glass containers.

Another way to increase the hardness of the container is to reduce the surface and internal cracks of the glass by adding powder to the wall heat, thus increasing the hardness of the glass candlestick and improving the quality of production. The detailed principle of this dusting method is: when the glass comes out of the molding mold of the bottle making machine, the multi-particle ammonium sulfate powder is putinto the bottle through the automatic duster, and then annealed in the annealing kiln.

The uniformity of the thickness of glass can be said to be one of the overall goals of the actual molding operation. Air compression or vacuum pumps used for blowing glass, unlike fixed molds, have an elastic boundary layer. Whether the thickness of the container can be evenly balanced depends on the temperature inside the bubble and the degree of diffusion of the sandwich glass material. Close it again to see if it is consistent with the actual operation of forming and what is the cause of uneven wall thickness:

1. The shoulder of the glass candlestick is thinner in some parts and cannot meet the required specifications. The thick wall defect of the bottle shoulder is caused by the fact that the relevant part of the blank has not been properly refrigerated or moisturized. The temperature is too high, or the blowing inspection is started too late, the material embryo is stretched too much.

2. The bottle body of glass candlestick is thinner. The key to this kind of defect is that the thickness of the glass candlestick itself or all the thickness specifications do not meet the specifications. The reason is often due to reheating of the prototype material. Too long time, the initial time delay of positive blowing inspection, will also cause uneven thickness of glass bottle wall, abrasive coating operation is not correct. Large or molded moulds are not suitable for refrigeration.

3.the bottom of the glass candlestick, glass candlestick bottom thickness does not conform to the standard specifications, prototype contact time is too long, or heating time is insufficient, low temperature storage tank block, widen the glass is not very good, back check start too early, or gas injection time too long, the bottle preheating, positive - start too early, or is blown inspection time is too long, Or punch needle (mandrel) timing execution time is not suitable.

The above is the reason for the hardness increase method and uneven wall thickness of glass candlestick.Sunny glassware Product quality is the major focus in Sunny. Sunny once demolished 80,000 pcs of glass vessel with barely visible blemish.